16 anooPCB maʻamaukūʻai ʻananā hemahema

I ke kaʻina hana PCB, ʻike pinepine ʻia nā ʻano hemahema, e like me ka soldering hoʻopunipuni, overheating, bridging a pēlā aku.Ma lalo iho e wehewehe ʻo PCBfuture i ka mea maʻamauHui PCBnā hemahema ke kūʻai aku i nā PCB a pehea e pale aku ai.

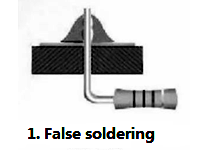

1. Hoʻopunipuni hoʻopunipuni

Nā hiʻohiʻona hiʻohiʻona: aia ka palena ʻeleʻele ma waena o ka solder a me ke alakaʻi ʻāpana, a i ʻole ke keleawe keleawe, a ua concave ka solder i ka palena.

Poino: ʻaʻole hana pono.

Ke kumu: ʻaʻole hoʻomaʻemaʻe ʻia ke alakaʻi o nā ʻāpana, ʻaʻole i hoʻopaʻa ʻia ka tin a i ʻole ʻoki ʻia ka tin.ʻAʻole hoʻomaʻemaʻe ʻia ka papa kaapuni i paʻi ʻia, a ʻaʻole maikaʻi ka maikaʻi o ka pulupulu ʻana.

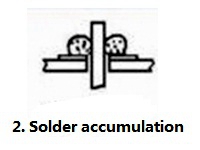

2. ʻO ka hōʻiliʻili solder

ʻO nā hiʻohiʻona hiʻohiʻona: ʻo ke ʻano o ka hui solder ua wehe, keʻokeʻo a ʻaʻole hoʻi.

ʻO ka pōʻino: ʻaʻole lawa ka ikaika mechanical hiki ke hoʻopiʻi hewa.

Ke kumu: maikaʻi ʻole ka maikaʻi o ka solder.ʻAʻole lawa ka mahana welding.Ke hoʻopaʻa ʻole ʻia ka solder, hemo ke alakaʻi.

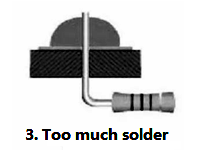

3. ʻOi loa ka solder

Nā hiʻohiʻona hiʻohiʻona: convex ka ʻili solder.

ʻO ka pōʻino: ʻaʻole i ʻike maʻalahi ʻia nā hemahema.

Ke kumu: hana hewa ʻole i ka wā kūʻai.

4. Li'ili'i solder

Nā hiʻohiʻona hiʻohiʻona: ʻoi aku ka liʻiliʻi o ka wahi kuʻi ma mua o 80% o ka pad, a ʻaʻole i hana ka solder i kahi hoʻololi maʻalahi.

Poino: lawa ole ka ikaika mechanical.

Ke kumu: maikaʻi ʻole ka neʻe ʻana o ka solder a i ʻole ka hemo ʻana o ka solder.ʻAʻole lawa ka lele.He pōkole loa ka manawa wili.

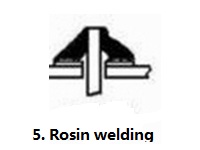

5. Kuʻiʻo Rosin

Nā hiʻohiʻona hiʻohiʻona: aia ka rosin slag i ka weld.

ʻO ka pōʻino: lawaʻole ka ikaika, maikaʻiʻole ka laweʻana, i kekahi manawa ma luna a ma waho.

Ke kumu: nui loa nā mīkini wiliwili a i ʻole ka welder hemahema.ʻAʻole lawa ka manawa wili a me ka wela.ʻAʻole i wehe ʻia ke kiʻi ʻoniʻoni o ka ʻili.

6. Ua wela loa

Nā hiʻohiʻona hiʻohiʻona: ka hui solder keʻokeʻo, ʻaʻohe luster metala, ʻili ʻili.

ʻO ka pōʻino: maʻalahi ka ʻili a hoʻemi ʻia ka ikaika.

ʻO ke kumu: nui loa ka mana o ka hao hao, a lōʻihi ka manawa hoʻomehana.

7. Kuʻi anuanu

Nā hiʻohiʻona hiʻohiʻona: He ʻeleʻele ka ʻili, a i kekahi manawa aia paha nā māwae.

Poino: Haʻahaʻa ikaika a maikaʻi ʻole ka conductivity.

Ke kumu: ua lulu ʻia ka solder ma mua o ka paʻa ʻana.

8. Hoʻokomo maikaʻi ʻole

Nā hiʻohiʻona hiʻohiʻona: ʻoi aku ka nui o ka pilina ma waena o ka solder a me ka weldment a ʻaʻole maʻalahi.

ʻO ka pōʻino: ikaika haʻahaʻa, ʻaʻohe komo a i ʻole ka manawa a i ʻole.

Ke kumu: ʻaʻole i hoʻomaʻemaʻe ʻia ka weldment.ʻAʻole lawa a maikaʻi ʻole ka maikaʻi o ka flux.ʻAʻole wela loa ka weldment.

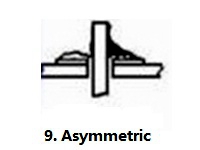

9. Asymmetric

Nā hiʻohiʻona hiʻohiʻona: ʻaʻole kahe ka solder ma luna o ka pad.

Poino: lawa ole ka ikaika.

ʻO ke kumu: maikaʻi ʻole ka wai o ka solder.ʻAʻole lawa ka flux a maikaʻi ʻole paha.ʻAʻole lawa ka wela.

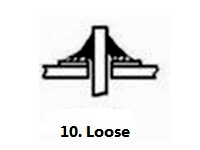

10. Wehe

Nā hiʻohiʻona hiʻohiʻona: Hiki ke hoʻoneʻe ʻia ke uea a i ʻole ke alakaʻi.

Ka pōʻino: ʻilihune a ʻaʻole hoʻokō.

Ke kumu: ma mua o ka paʻa ʻana o ka solder, neʻe ka uea alakaʻi e hoʻoheheʻe.ʻAʻole hana maikaʻi ʻia ke alakaʻi.

11. Cusp

Nā hiʻohiʻona hiʻohiʻona: ʻoi.

ʻO ka pōʻino: maikaʻi ʻole ka nānā ʻana, maʻalahi ke kumu o ka hoʻopili ʻana

ʻO ke kumu: liʻiliʻi ka lele a lōʻihi loa ka manawa hoʻomehana.ʻAʻole kūpono ka haʻalele ʻana o ka hao hao.

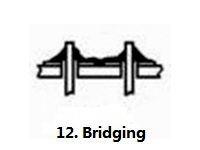

12. Ke alahaka

Nā hiʻohiʻona hiʻohiʻona: pili nā uea pili.

Poino: Kaapuni pōkole uila.

Ke kumu: nui loa solder.ʻO ke kihi kūpono ʻole o ka hoʻihoʻi ʻana o ka hao hao.

13. Puka

Nā hiʻohiʻona hiʻohiʻona: ʻike ʻia ka nānā ʻana a i ʻole nā mana haʻahaʻa haʻahaʻa e ʻike i nā lua.

ʻO ka pōʻino: lawa ʻole ka ikaika, ʻoi aku ka maʻalahi o ka hoʻoheheʻe ʻana i ka hui solder.

ʻO ke kumu: ʻoi aku ka nui o ka ʻokoʻa ma waena o ke poʻo a me ka lua pad.

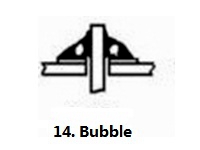

14. Buhu

Nā hiʻohiʻona hiʻohiʻona: aia kahi puʻupuʻu solder hanu ahi ma ke kumu o ke alakaʻi, a hūnā ʻia kahi lua i loko.

ʻO ka pōʻino: ka lawe ʻana i kahi manawa, akā maʻalahi ke hoʻokau maikaʻi ʻole no ka manawa lōʻihi.

ʻO ke kumu: nui ka ʻokoʻa ma waena o ke alakaʻi a me ka lua disc welding.ʻAʻohe hoʻokomo kepau.He lōʻihi ka manawa wili o ka hoʻopili ʻana i nā lua ʻaoʻao ʻelua, a hoʻonui ka ea i loko o nā lua.

15. Hoʻopaʻa ʻia ke keleawe keleawe

Nā hiʻohiʻona hiʻohiʻona: ʻili ʻia ka pahu keleawe mai ka papa i paʻi ʻia.

Poino: Ua poino ka PCB.

ʻO ke kumu: lōʻihi loa ka manawa wili a kiʻekiʻe loa ka mahana.

16. E hemo

ʻO nā hiʻohiʻona hiʻohiʻona: ʻili nā hui solder mai ka pahu keleawe (ʻaʻole ke keleawe keleawe a me ka PCB).

Poino: Kaapuni hamama.

Ke kumu: ʻino ka uhi metala ma ka pā.

Hāʻawi ʻo PCBFuture i nā lawelawe hui PCB āpau, me ka hana ʻana i ka PCB, ka ʻāpana ʻāpana a me ka hui PCB.ʻO kā mākoulawelawe PCB Turnkeyhoʻopau i kou pono e hoʻokele i nā mea hoʻolako he nui i nā manawa he nui, e hopena i ka hoʻonui ʻana i ka pono a me ka maikaʻi o ke kumukūʻai.Ma ke ʻano he ʻoihana alakaʻi maikaʻi, pane piha mākou i nā pono o nā mea kūʻai aku, a hiki iā mākou ke hāʻawi i nā lawelawe i ka manawa a me ka pilikino i hiki ʻole i nā hui nui ke hoʻohālike.Hiki iā mākou ke kōkua iā ʻoe e pale aku i nā hemahema kūʻai PCB i kāu huahana.

Ka manawa hoʻouna: Nov-06-2021